Johneturbo

|

| posted on 24/9/15 at 05:49 PM |

|

|

Making a mould/buck

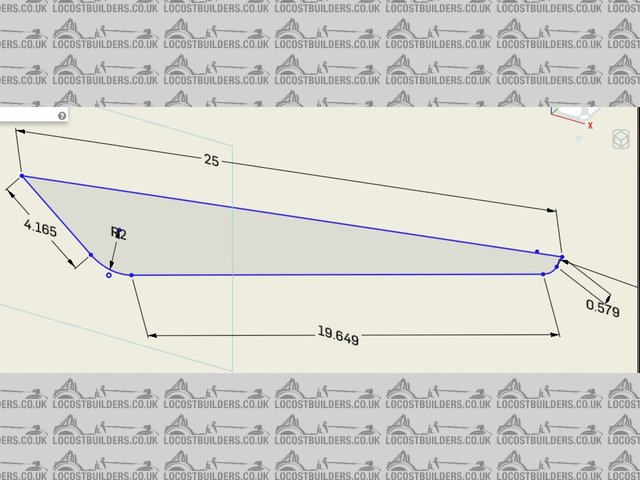

What would be a good way of making this shape?

Description

What I'd like to be able to do is make some templates out of card/wood then fill the gaps with celotex then sand down to get the shape, then

take a mould from that.

something like what Easy Composites describe on youtube https://www.youtube.com/watch?v=XeeSsmsm9h0

my head hurts with trying to think of ways to make it

|

|

|

|

|

daniel mason

|

| posted on 24/9/15 at 07:31 PM |

|

|

Ask Andrew Jackson (unijacko67)

He's done a full shell in c/f

[Edited on 24/9/15 by daniel mason]

|

|

|

JC

|

| posted on 24/9/15 at 09:18 PM |

|

|

If it is a single curvature, make it out of light ally and use that as the mould?

[Edited on 25/9/15 by JC]

|

|

|

Johneturbo

|

| posted on 25/9/15 at 09:56 AM |

|

|

i want to make two the same but for the other side, I've had a go with cad but I find it hard to use and replicate

these are the shapes i've come up with, I would like to print it off full size so I can then cut out the shape

these two are the top and bottom I have an idea of making 3 more sections in the middle then fill the space with foam then shape down to the

template

Description

Description

|

|

|

HowardB

|

| posted on 25/9/15 at 10:42 AM |

|

|

just a thought,.... especially since you want a mirror image,...

make a cardboard template, and then walk round a scrap yard looking for a car with a similar panel shape,. might be a bit of a jag front wing or

something similar, buy the pair of scrap parts, trim to size, fill, polish to make the buck, and then proceed....

hth

Howard

Fisher Fury was 2000 Zetec - now a 1600 (it Lives again  and goes zoom) and goes zoom)

|

|

|

Irony

|

| posted on 25/9/15 at 10:51 AM |

|

|

I might carve the shape from a block of MDF. The MDF can then be sprayed and waxed to make a mould from. Either that or from a polystyrene block.

But with polystyrene you have to cover it with either filler and sand (time consuming and requires a delicate hand) or covering the poly in tin foil

(to prevent it from melting when contacting the resin). Tin foil is a quick solution but it leaves a tin foil finish on the mould.

|

|

|

40inches

|

| posted on 25/9/15 at 10:57 AM |

|

|

Could you form the curved part in

Bendable MDF?

I did what Irony suggests to make a buck for this:

Air Duct

Layers of 18mm MDF, then filled in the steps with body filler

[Edited on 25-9-15 by 40inches]

|

|

|

emsfactory

|

| posted on 25/9/15 at 10:58 AM |

|

|

You could make a blow mould. Blow one way for one side then reverse the mould and blow the other way for the other side. Should be pretty close to

being exactly opposite.

|

|

|

Johneturbo

|

| posted on 25/9/15 at 11:09 AM |

|

|

Great suggestions guys.. never knew there was bendable mdf! I even had a look around a garden centre as window boxes are almost the shape, but not

really the right size

my idea was to try and work out how to print my templates in full scale then use them to make say the formers, I should then be able to cut out 2 x

for both sides then they should be the same

i'll have to google blow mould

|

|

|

Johneturbo

|

| posted on 2/10/15 at 02:53 PM |

|

|

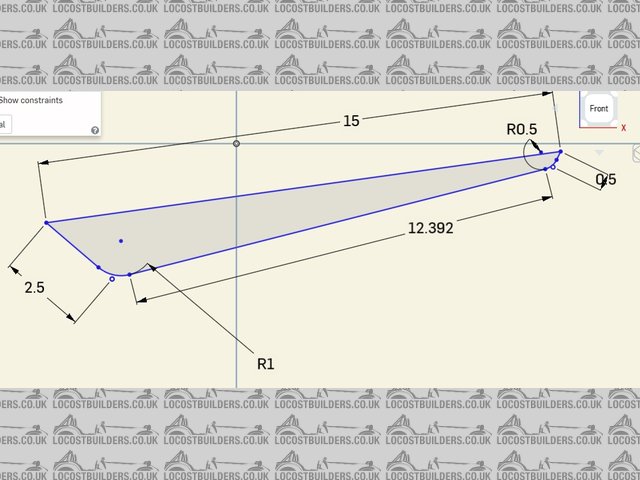

I've been making a little progress with my mould/buck

I made this out of card, via my templates, next step is to make the formers out of 12mm mdf then fill the voids with PU foam blocks

Description

Description

what do you guys think?

|

|

|

Rosco86

|

| posted on 7/10/15 at 07:24 AM |

|

|

looking good!

My Build Thread

|

|

|