scoop

|

| posted on 27/8/12 at 06:12 PM |

|

|

Will be interested to know how you get on so keep us updated

|

|

|

|

|

RobBrown

|

| posted on 1/9/12 at 05:25 PM |

|

|

A bit of an update...

Thanks to Dan @ www.danstengineering.co.uk/

I have a bike fuel pump, and after a bit of faff (running electric to back of bar!) it is now fitted.

However it doesn't seem to have made a difference to the lack of power, so...

I marked the throttle position to try and work out where abouts in the range the issue develops.

It seems to be just beyond 1\4 up to 3\4 when the issue kicks in. I can see this whilst stationary on the drive as the engine starts to splutter and

struggle at the higher RPM.

On this website it states

'If the engine has problems between 1/4 and 3/4 throttle, the jet needle and needle jet (most likely the jet needle) is likely the

problem.'

So I moved the jet needle down a notch to one up from bottom. I had moved it back to middle after drilling the main jet to 1.6mm.

This made it worse, i think?

Is it likely that I need to lower the needle to pos 2, to make it leaner?

Where is the needle jet - Is this likely to need drilling out?

Any further advice appreciated... I'm just starting to understand these carbs, just missing that vital piece of info to make them tunable (by me

- before getting them to RR).

|

|

|

David Jenkins

|

| posted on 1/9/12 at 05:37 PM |

|

|

This all sounds similar to the problem I had... everyone said "drill the jets to 1.6mm", so I did. When I got to wide open throttle the

engine would cough, splutter and bog down something 'orrible.

Finally got myself an AFR meter and when I plugged it in I found that the mixture was way too rich when the throttle was wide open - I ended up making

myself a new set of jets drilled to 1.3mm, which worked perfectly.

Unfortunately I don't have adjustable needles, as my mid-throttle AFR is a bit rich - if I could improve that my settings would be perfect.

The moral of the story? Get to a rolling road, or invest in an AFR meter.

|

|

|

maccmike

|

| posted on 1/9/12 at 06:01 PM |

|

|

yeah Im not keen on jets being drilled until other options have been covered.

Have you set the pilot screw to factory?

|

|

|

RobBrown

|

| posted on 1/9/12 at 06:10 PM |

|

|

quote:

Originally posted by maccmike

yeah Im not keen on jets being drilled until other options have been covered.

Have you set the pilot screw to factory?

I thought this was a tried and trusted route. I can solder and redrill?

2.5 turns. Any less and it doesn't start.

|

|

|

x_flow57

|

| posted on 1/9/12 at 06:28 PM |

|

|

quote:

Originally posted by David Jenkins

This all sounds similar to the problem I had... everyone said "drill the jets to 1.6mm", so I did. When I got to wide open throttle the

engine would cough, splutter and bog down something 'orrible.

Finally got myself an AFR meter and when I plugged it in I found that the mixture was way too rich when the throttle was wide open - I ended up making

myself a new set of jets drilled to 1.3mm, which worked perfectly.

Unfortunately I don't have adjustable needles, as my mid-throttle AFR is a bit rich - if I could improve that my settings would be perfect.

The moral of the story? Get to a rolling road, or invest in an AFR meter.

Good advice with an AFR meter but don't forget David you are running A 1600 x-flow and the op has a 2 0 pinto.

I have just got a pinto sounding good with 170mains and my 2.0 zetec on the rolling road needed 230.

Sort WOT then needle and finally idle jets.

Hope that helps.

Nick

|

|

|

David Jenkins

|

| posted on 1/9/12 at 06:32 PM |

|

|

True - but what I'm trying to say (badly) is that drilling out the jets may not be the ideal answer without some measurement tool, especially

when the symptoms as so similar to those I experienced.

|

|

|

RobBrown

|

| posted on 1/9/12 at 07:18 PM |

|

|

quote:

Sort WOT then needle and finally idle jets.

Hope that helps.

Nick

What does WOT mean?

Also

I don't have a lambda boss in my exhaust, to be able to fit an AFR meter. I have a 4-1 collector on the outside of the car, so fitting one is

going to be quite far away from the engine - will that matter?

|

|

|

RobBrown

|

| posted on 1/9/12 at 07:32 PM |

|

|

quote:

What does WOT mean?

Found it - Wide Open Throttle

|

|

|

RobBrown

|

| posted on 15/9/12 at 01:11 PM |

|

|

Hi all

Another update on this, I think I am moving forward...

I bought an Innovate LC-1 with Bosch O2 sensor, which got delivered yesterday (always good to get toys in the post). Spent this morning sorting out

the tails etc (if you've got one you'll know what I mean!). (always good to get toys in the post). Spent this morning sorting out

the tails etc (if you've got one you'll know what I mean!).

This is plugged into my laptop using LogWorks 3 - This has the added advantage of tracking the changes and smoothing out what it is showing.

I ran the engine - inititally AFR was up at around 16 but once the engine warmed up it settled in at around 14.5 - which according to other threads

is about right

So went for WOT and the AFR dipped to around 10. So my first question is - Is this too rich?

Second question - What should it be at WOT. I've read anywhere between 12 and 14?

Third question- If I need to swap the main jets for smaller, is there an algorithm of some sort that says I should try 1.4.

I could solder and redrill before committing to £12 per set of bought jets - seems like a plan.

Am I reading this all right?

Thanks

Rob

[Edited on 15/9/12 by RobBrown]

|

|

|

RobBrown

|

| posted on 15/9/12 at 06:48 PM |

|

|

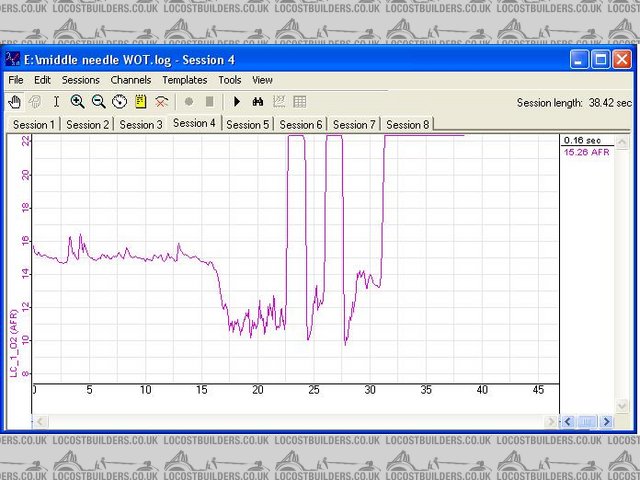

Some photos

Engine started to pulse at half throttle

Pulsing at Half throttle

So moved needle to middle and got to WOT but still too Rich

WOT after needle moved to mid

Main Jet is at 2.0mm as I could only go to 1.6 in smaller increments, The ideal will be somewhere between the two I suspect.

No Air filter fitted, so may have to do this as it restricts air flow and therefore affects AFR. Will fit before I do too much more!

|

|

|

RobBrown

|

| posted on 29/9/12 at 07:42 PM |

|

|

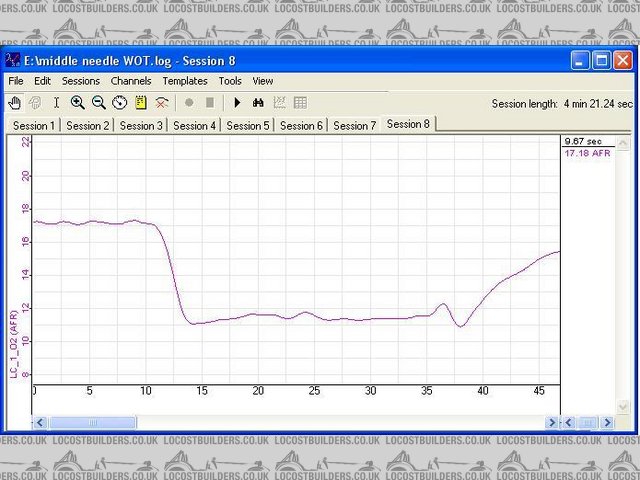

Hi All,

For those that are interested, an update...

I've now fitted a Pipercross PX600 air filter.

Now with the LC-1 I'm able to properly see what's going on.

The long and short of it is that I'm down to 120 Mains and 15 Idle jets, and the car is starting to pull a lot better. I've 17.4 idles to

fit as I've turned the mixture screw out quite a lot.

With the 120's in I still get an AFR reading of 11.2, with idle at 13.2, and bogging down on acceleration.

I can hear and feel the difference in the engine the lower the jet goes! And the throttle response is a lot better

Just can't believe that I'll probably end up between 100 and 110! So far away from the 1.6mm as always recommended when the question is

asked here on LB.

Just now doubting my engine is a 2.0 litre

|

|

|